Harness taping machines introduction

Tape wraps

Like all wire harnessing materials, play a vital part in creating a cost-effective and reliable electrical interconnect system.

A tape wrap jacketing installation is a highly inefficient and costly harnessing solution. Although the tape materials are extremely versatile and appear inexpensive at the buyer level, the finished assembly cost will generally be high because tape wrapping is a very labor-intensive process. Furthermore, tape wrapping is a “craft sensitive” process and the finished installation can vary from installer to installer.

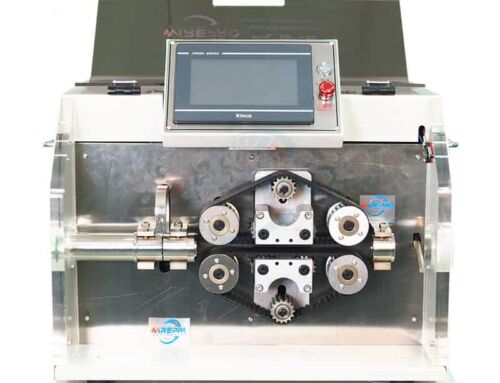

Automatic wire tube taping machine

WIREPRO provides several model machines for different kinds of harness taping methods, to help improve the working affection and make sure the quality of the finished product.

Cable taping machines function comparison table

More introduction of harness taping machine

HW-D25 supports wire harness continuous & spot taping. It can work with different types of material tape without back paper, such as cloth tape, PVC tape, etc. It’s mostly used for continuous taping.

HW-D30 is a powerful machine, the feeding roller can automatic feeding wire harness. Supporting a variety of tape wrapping methods, especially overlap taping.

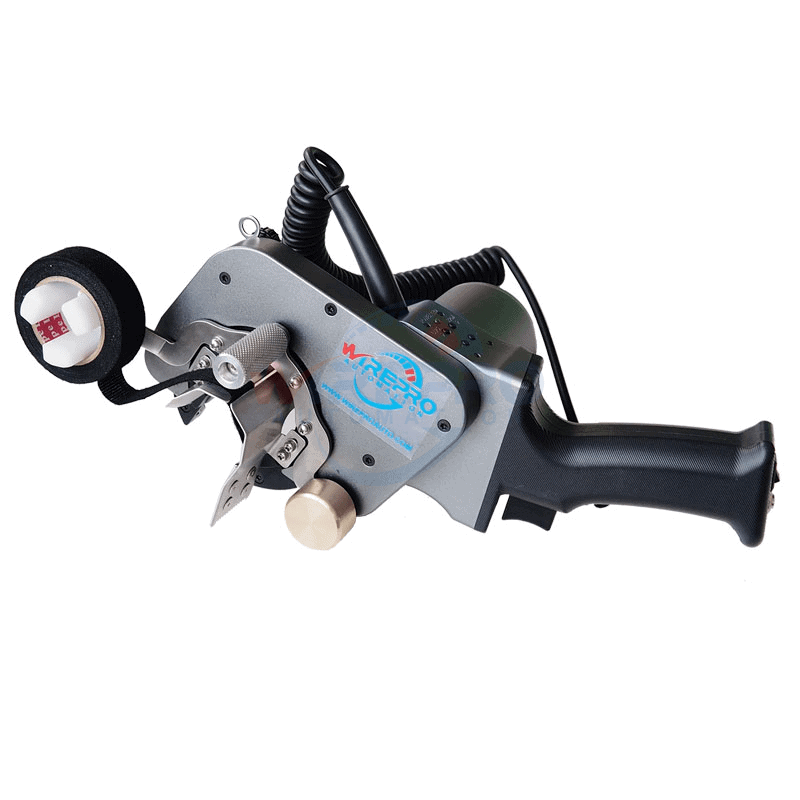

HW-H35 supports wire harness continuous & spot taping. With this hand-held device, the wire harness can be high-quality wrapped with various tapes.

HW-HD35 supports wire harness continuous & spot taping. Very good for big diameter harness taping and branch taping.

The HW-S05 is designed for tape point wrapping. It can work with different types of material tape include tape with back paper. Mainly used for automobile, motorcycle, and aviation industry, point taping for marking, fixing, or insulation.

If you need more info about the machine, feel free to contact WIREPRO!