Are you looking for a solid wire 2D bending machine to improve production efficiency?

You came to the right place!

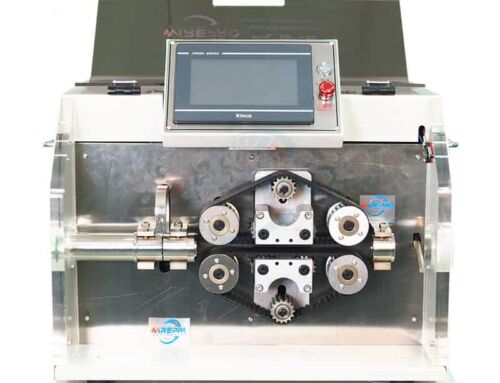

WIRPEO Automation provides full automatic wire cutting stripping bending machine for solid one conductor wire or steel wire.

Solid wire bending machine details:

Solid wire bending machine

Introduction:

This series machine is used for cutting, stripping, and bending hard wires. Support two wire ends stripping and different shapes bending. Suitable for the jumper wire of the electric control cabinet, bending wire of the meter box, forward and reverse jumper wire of the contactor, table box, watch cabinet and other hard wires that need to be bend and stripping etc.

Features:

1. Support almost arbitrarily adjust angle and bending length

2. Excellent bending consistency, and eliminate manual operation error

3. Automatic stripping and bending, improve work efficiency

4. Equip with Shangyin linear slide, precision pneumatic pressure roller, more precision, more complete functions.

Application:

Jumper bending machine

Solid wire cut strip bend machine

Some tips you may concern about how to buy from WIREPRO:

Support TT, Credit Card, PayPal multiple payment methods.

Ship via Sea and Air transportation, DHL door to door just needs 3-5days.

One-year quality warranty, the professional team guarantees after-sales service.

Please feel free to contact us get the total cost!

Key process requirements for blade stripping process:

– Condition of wire/cable – correct type(traceability), no damages, no twisting, etc;

– Handling of wire/cable during stripping process;

– Maintenance of stripping tool: conditions of blades, calibration;

– Correct SW program according to datasheet dimensions, precision (stripping length);

– Machine error self-detection, the risk to mix.

Also, visual check for no damages, no missing/damaged strains, good insulation cut quality.

Contact WIREPPRO to get quotes today!