What is Nylon Braid Race Hose?

Nylon braid hose, featuring a robust outer nylon braid and an inner hose made of rubber or PTFE (Polytetrafluoroethylene), is a highly versatile and reliable tubing solution.

Nylon braid hose consists of two primary components: an inner hose and an outer nylon braid. The inner hose is typically made of either rubber or PTFE, depending on the specific application requirements. Rubber inner hoses offer excellent flexibility and compatibility with a wide range of fluids, while PTFE inner hoses provide exceptional chemical resistance and high-temperature capabilities. The outer nylon braid is tightly woven around the inner hose, providing additional reinforcement and protection against abrasion, impact, and environmental factors.

What’s the Main Applications of Nylon Braid Hose?

Nylon braid hose finds extensive use in various industries due to its exceptional performance characteristics. Some of its main applications include:

Automotive Industry: Nylon braid hose is commonly used in automotive applications such as fuel lines, brake systems, power steering systems, and coolant lines. The combination of durability and flexibility makes it suitable for handling diverse fluids and withstanding the rigors of automotive environments.

Industrial Machinery: In industrial settings, nylon braid hose is utilized for fluid transfer in hydraulic systems, lubrication lines, and pneumatic systems. Its robust construction and resistance to abrasion make it ideal for demanding industrial applications.

Chemical and Pharmaceutical Industries: Nylon braid hose with a PTFE inner hose finds significant use in chemical and pharmaceutical industries. The PTFE material offers exceptional resistance to a wide range of corrosive chemicals and high temperatures, making it suitable for transferring aggressive fluids safely.

How to Efficiently Cut Nylon Braid Hose?

Nylon braid hose is typically sold in rolls or on tube spools and often needs to be cut into shorter lengths for use after purchase.

Traditionally, this process involves manual cutting using a sharp utility knife, a measuring tape or ruler, and the use of tape to seal the cut edge and prevent the nylon braid from unraveling. However, this method has certain drawbacks, including large cutting length tolerances, uneven cutting surfaces, and the labor-intensive task of manually applying tape for sealing.

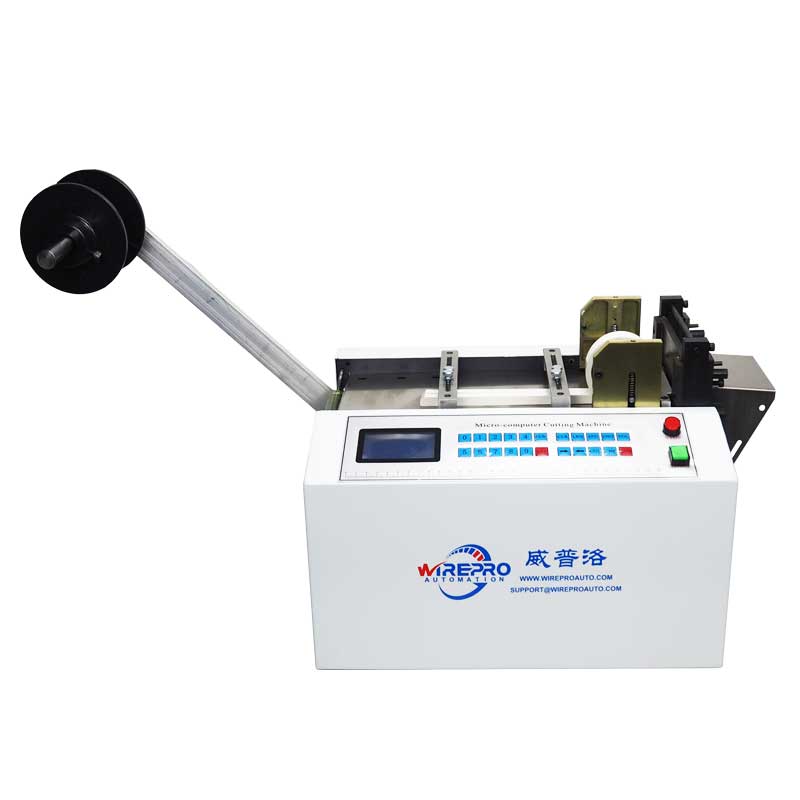

To address these challenges and meet customer needs, our company has introduced a specialized equipment called the CB-T15.

This cutting machine is designed to automate the cutting process according to the desired pipe length.

It also incorporates a pre-cut sealing mechanism, ensuring that the cut edge is securely sealed with tape.

The CB-T15 delivers precise and flat cutting surfaces, accurate lengths, and significantly improves production efficiency by eliminating the need for manual tape application.

Currently, the CB-T15 is suitable for pipe diameters up to 15mm, but we can also customize the equipment to accommodate other sizes based on specific requirements.

You can check the details: CB-T15

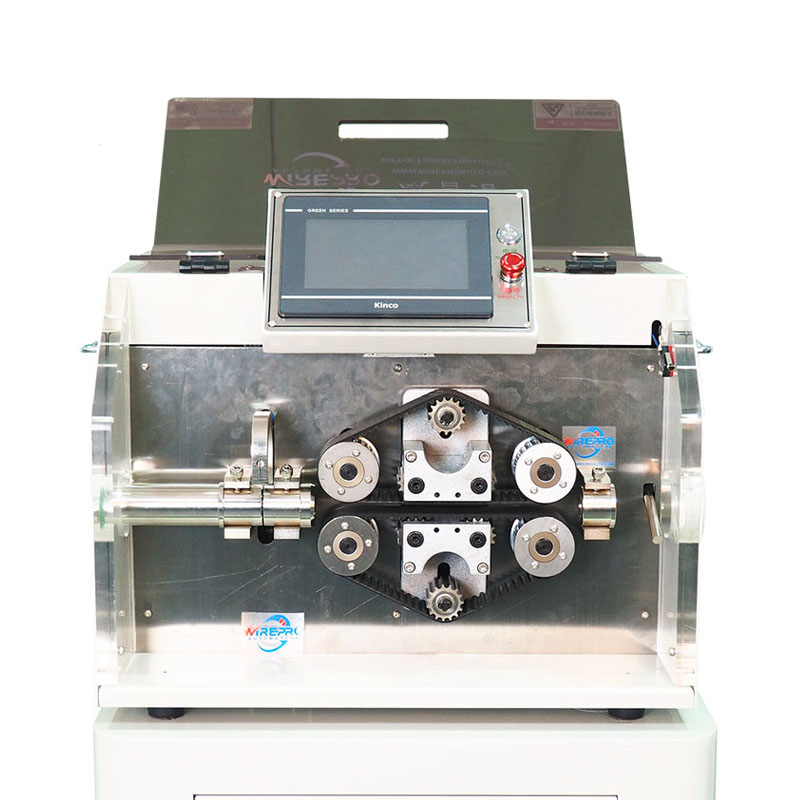

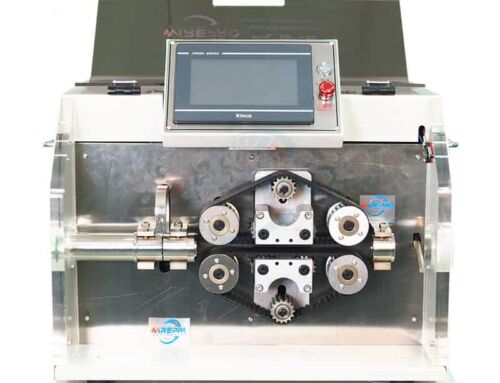

More Hose Cutting Machines

For customers who do not require tape sealing and are looking for cost-effective cutting equipment, we offer the following standard options: