1. Engineering production preparation

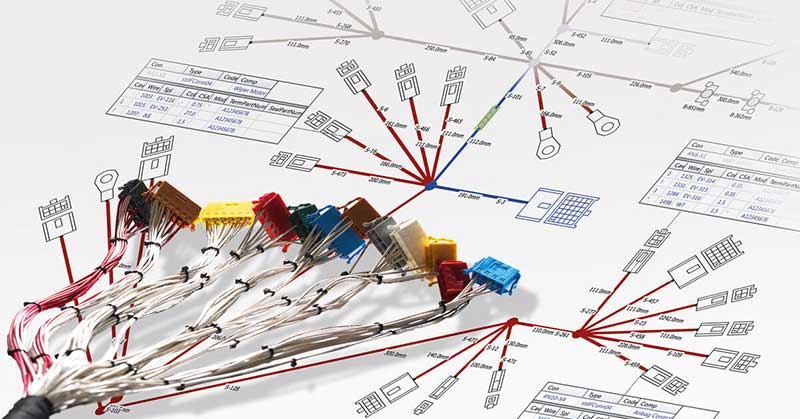

The harness engineer is assigned to produce a 100% accurate, error-free data set—per variant/derivative—that can be fully costed and passed on to production for assembly. He/she must generate the full BOM and validate it against the design intent. The engineering phase of the process brings theory and planning face to face with reality, manage discretionary steps including:

– Component selection: Wires, terminals, seals, plugs, tapes, tubes must accommodate customer specifications

– Splice position optimization and balancing: Here the harness builder must meet manufacturing and quality rules, including customized rules such as the choice of waterproofing materials (i.e., heat- shrink sleeves).

– Wire-color optimization: The harness provider must allocate wire-color definitions for manufacturing and service while taking the wire inventory into account:

– Component sourcing verification

– Assembly time calculation/prediction

– BOM calculation

– Prepare the drawings that will be used in manufacturing.

2. Process preparation

After all engineering planning suppliers must develop a process preparation system in accordance to Lean manufacturing requirements. Full component traceability must be assured (batch, date code, delivery date) and traceability data must be recorded per finish good batch number. Different component batches must not be mixed together. Storage of components online and in-process also must be assured with full traceability. Handling of components at the line and during the process must eliminate the risk of damage and prevent component mixing.

3. Start of production

Each start of production must be linked to a specific production batch (finish good batch). For the preparation of the line supplier must develop a startup checklist where all process workstations parameters, necessary gauges, equipment and parameters, prove of maintenance and operator training requirements are listed. Quality leaders together with line leaders must validate this checklist and verify that process is ready for production.