Plastic pipes can be classified based on their hardness, which is often determined by the specific type of plastic used in their construction. Here are some common plastic pipes categorized according to their hardness:

Rigid Plastic Pipes:

Polyvinyl Chloride (PVC) pipes: PVC pipes are rigid and offer excellent strength and durability.

They are commonly used for water supply, drainage, irrigation, and plumbing systems.

Polypropylene (PP) pipes: PP pipes are rigid and resistant to chemical corrosion. They find applications in industrial processes, wastewater treatment, and chemical transportation.

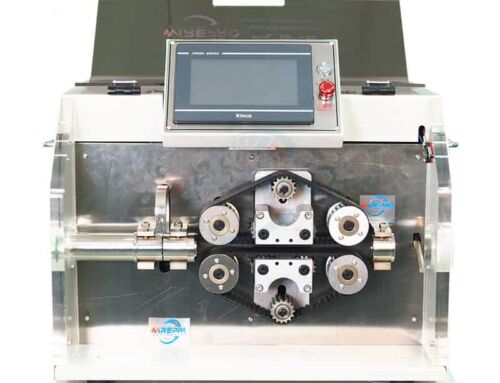

Hard tubes are usually cut with rotary knives, larger diameter tubes can be cut with hand tools, and smaller diameter can be cut with rotary knife automatic cutters. WIREPRO recommends the following equipment:

Semi-Rigid Plastic Pipes:

Polyethylene (PE) pipes: PE pipes are semi-rigid and have good flexibility while maintaining structural integrity. They are widely used for water supply, gas distribution, and irrigation systems.

Cross-linked Polyethylene (PEX) pipes: PEX pipes are semi-rigid and offer excellent resistance to high temperatures and chemicals. They are commonly used for plumbing and radiant heating systems.

Semi-rigid tubing can be cut with a rotary knife or with a thinner blade depending on the situation. WIREPRO recommends the following equipment:

Flexible Plastic Pipes:

Polyvinyl Chloride (PVC) Flexible pipes: These pipes are made of a softer PVC material that allows for increased flexibility. They are commonly used for applications requiring bending and maneuverability, such as in portable water hoses, swimming pool circulation systems, and irrigation.

If the tube wall is thin enough to be crushed then we can cut it with a flat feed wheel type of equipment which is less expensive:

Corrugated Plastic Pipes:

High-Density Polyethylene (HDPE) corrugated pipes: HDPE corrugated pipes are flexible and have a corrugated exterior for added strength. They are commonly used for drainage, stormwater management, and underground utility installations.

Polypropylene (PP) corrugated pipes: PP corrugated pipes are lightweight and flexible. They are used for applications such as cable protection, ventilation systems, and agricultural drainage.

Corrugated tubes are malleable and most importantly maintain the cutting tolerances of the equipment:

It’s important to note that the hardness of plastic pipes can vary within each category depending on factors such as wall thickness and reinforcement. Reinforcement methods for plastic pipes are used to enhance their structural integrity, strength, and durability, especially in applications where they are subjected to high pressure, temperature, or external loads.

Commonly used reinforcement methods for plastic pipes, for example, Fiber Reinforcement. Fiberglass (GRP/GRE), Carbon Fiber Aramid Fiber or Aramid fibers are all ok for Reinforcement tube strength. When there are these reinforced parts, choose equipment with better cutting force.