Introduction

Injection molding has revolutionized the manufacturing industry by enabling the mass production of intricate and precise plastic components. At the heart of this transformative process lies the injection molding machine, a sophisticated piece of equipment that plays a pivotal role in the production of a wide range of products. In this article, we will delve into the world of injection molding machines, examining their classifications, applications, and key characteristics.

Classification of Injection Molding Machines

Injection molding machines come in various types, each designed for specific applications and production requirements.

The primary classifications based on power include:

Hydraulic Injection Molding Machines

Electric Injection Molding Machines

Hybrid Injection Molding Machines

Hybrid machines combine hydraulic and electric systems to harness the advantages of both.

They offer high performance, energy efficiency, and flexibility, making them versatile for various applications.

The primary classifications based on machine structure include:

Two-Platen Injection Molding Machines

Vertical Injection Molding Machines

Vertical machines have a vertical mold configuration, making them ideal for overmolding and insert molding.

They save floor space and are often used for producing smaller, more specialized components.

WIREPRO supply the Hybrid Injection Molding Machines and Vertical Injection Molding Machines machines

Applications of Injection Molding Machines

Injection molding machines find extensive use across diverse industries. Some notable applications include:

Automotive Industry:

Injection molding machines produce various automotive parts, such as dashboards, bumpers, and interior components.

Consumer Goods:

Common household items like toys, containers, and kitchen appliances are manufactured using injection molding.

Medical Devices:

Precision and repeatability make injection molding machines ideal for producing medical components like syringes, IV connectors, and surgical instruments.

Electronics:

Injection molding is crucial in manufacturing electronic enclosures, connectors, and housing for gadgets and devices.

Packaging:

The packaging industry relies on injection molding for producing bottles, caps, and packaging materials.

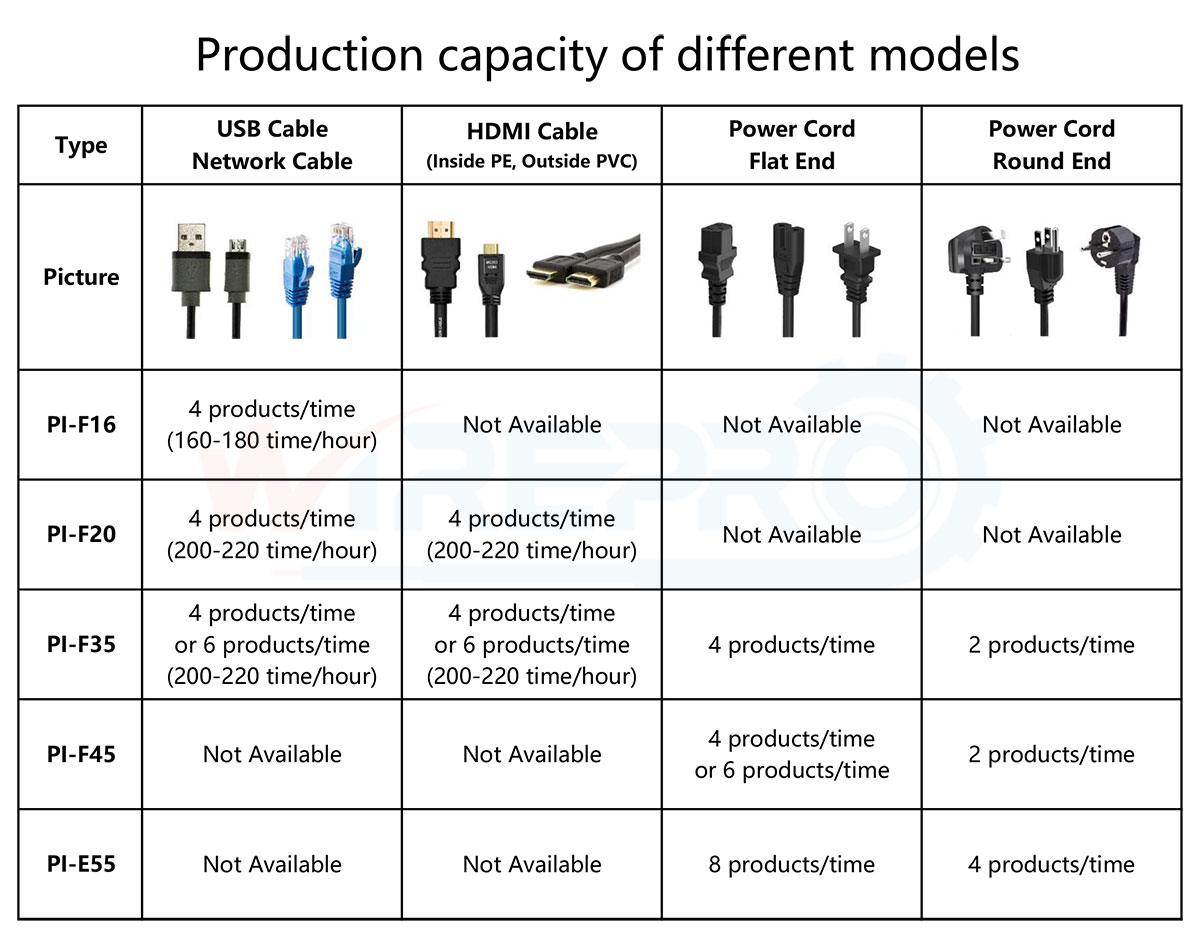

Capacity Comparison of Different Models